Automated Dental

Post-Processing Systems

High-performance equipment designed for dental labs and production centers. From intelligent cleaning to robotic trimming, our specialized units ensure precision, consistency, and efficiency in your daily workflow.

Industrial Grade

Built for continuous 24/7 operation and stability.

Intelligent Control

Vision-guided systems and robotic precision.

High Efficiency

Significantly reduce manual labor and error rates.

Post-Processing Ecosystem

From Step 1 to Step 4: A seamless automated journey for every aligner.

RFADM-03 Spinner

Centrifugal Cleaning for Batch Production

Developed for both high-temp resistant dental model resin & water-washable resin. The high-speed centrifugal action gives quick and exceptional results, ensuring models are 100% clean for thermoforming.

- Solvent or Water: Compatible with IPA/Ethanol or Water

- 380Kg Weight: Heavy-duty stability

- Silent Operation: Industrial grade motor

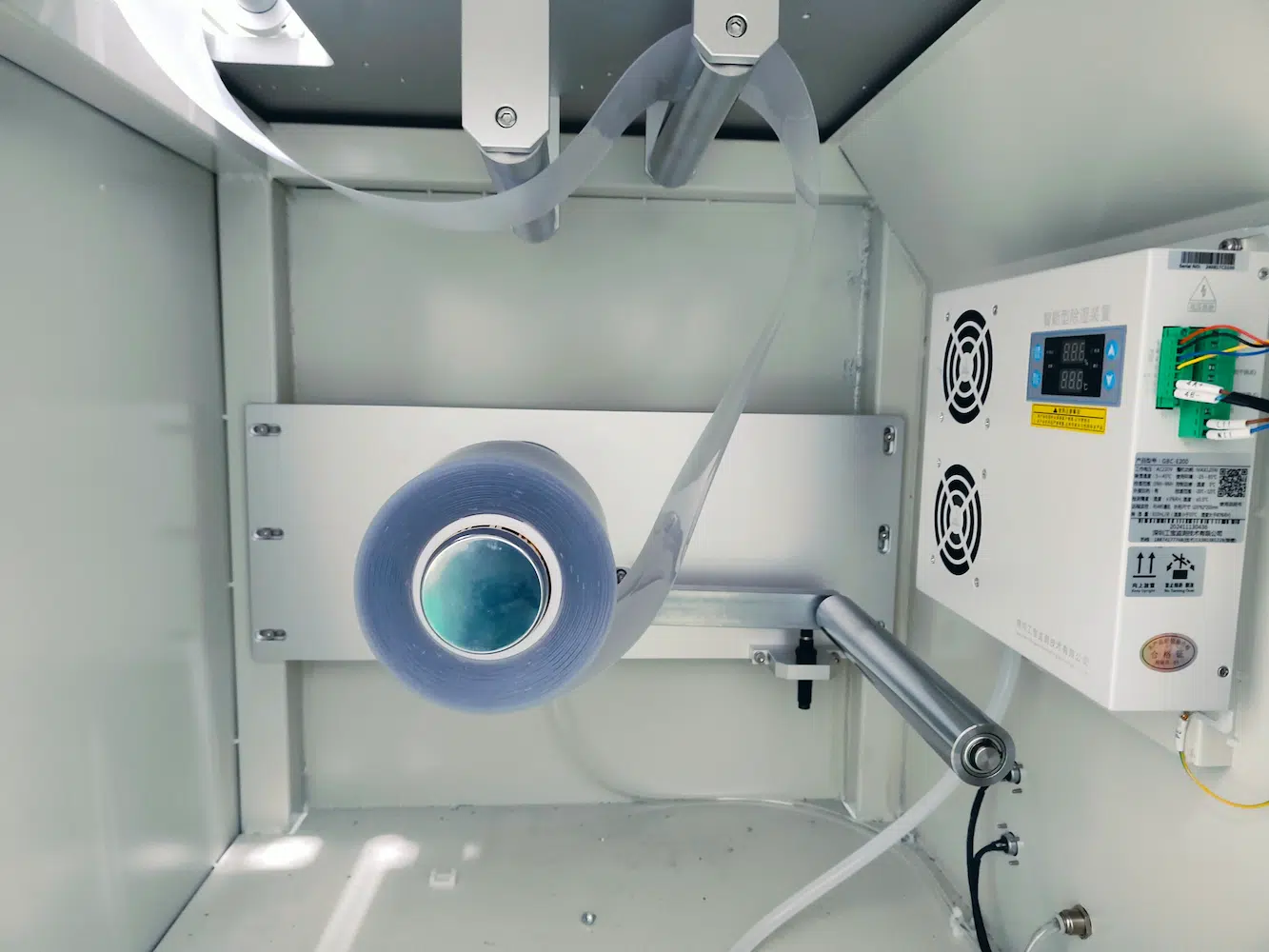

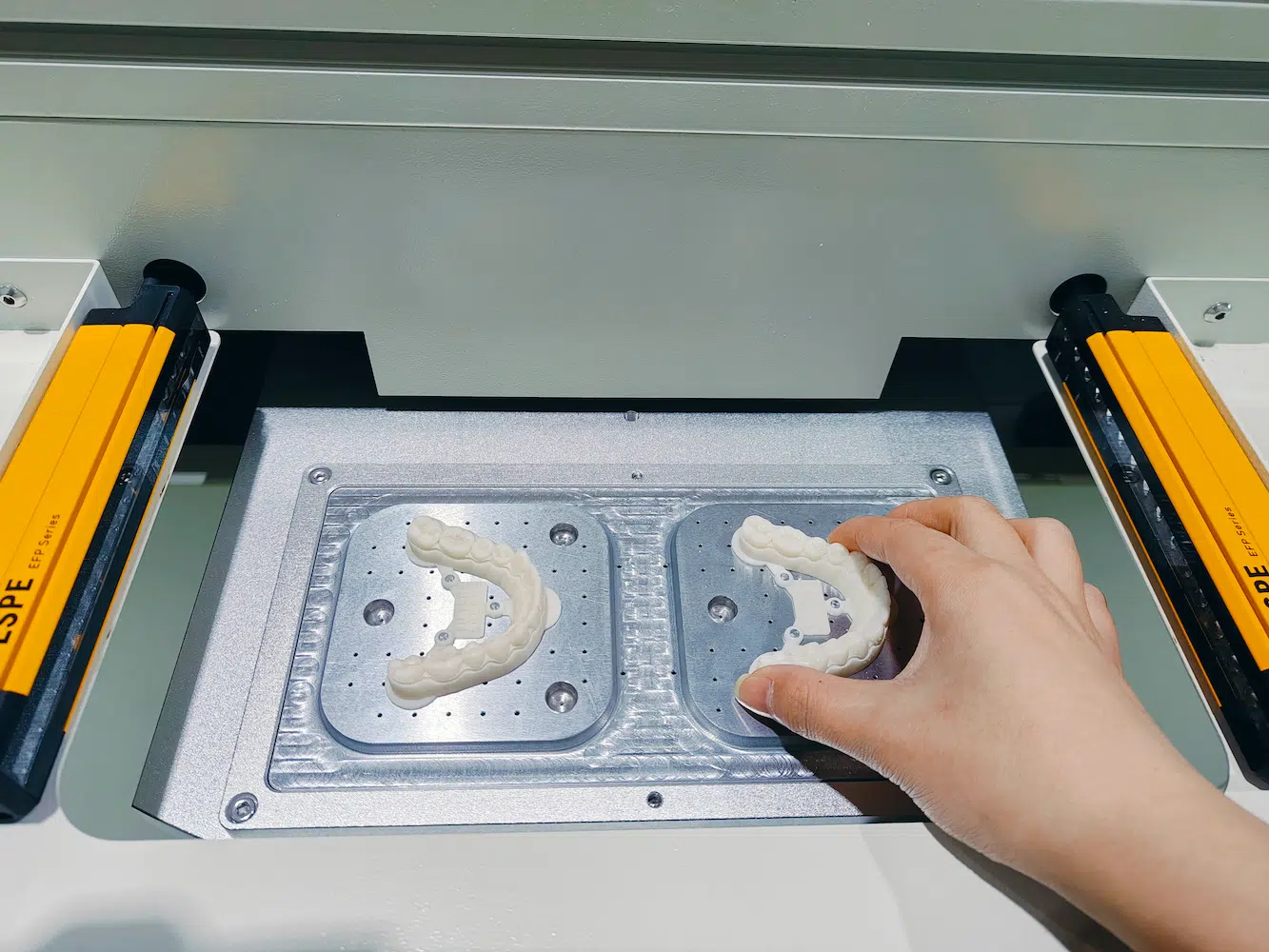

Automatic Thermoforming

Roll-Feed High Speed Forming

Automated roll feeding with dual-mold capability. Precise temperature control ensures perfect adaptation of the aligner film to the model, critical for orthodontic forces.

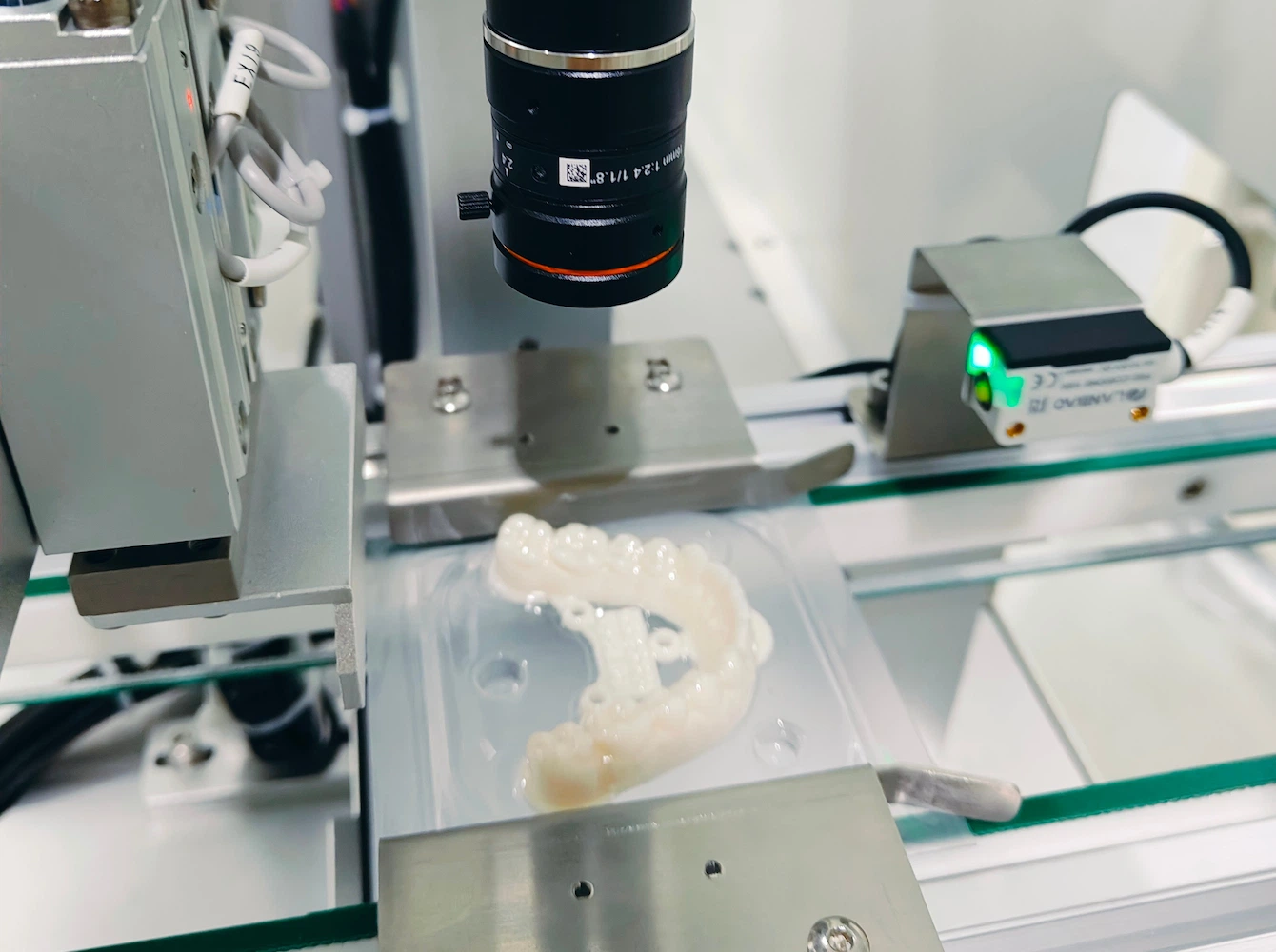

Laser Marking

Vision-Guided Green Laser

Uses a 532nm Green Laser (cold light) to mark clear aligners without burning or deformation. The integrated vision system automatically identifies the marking area, and the flip mechanism handles double-sided requirements.

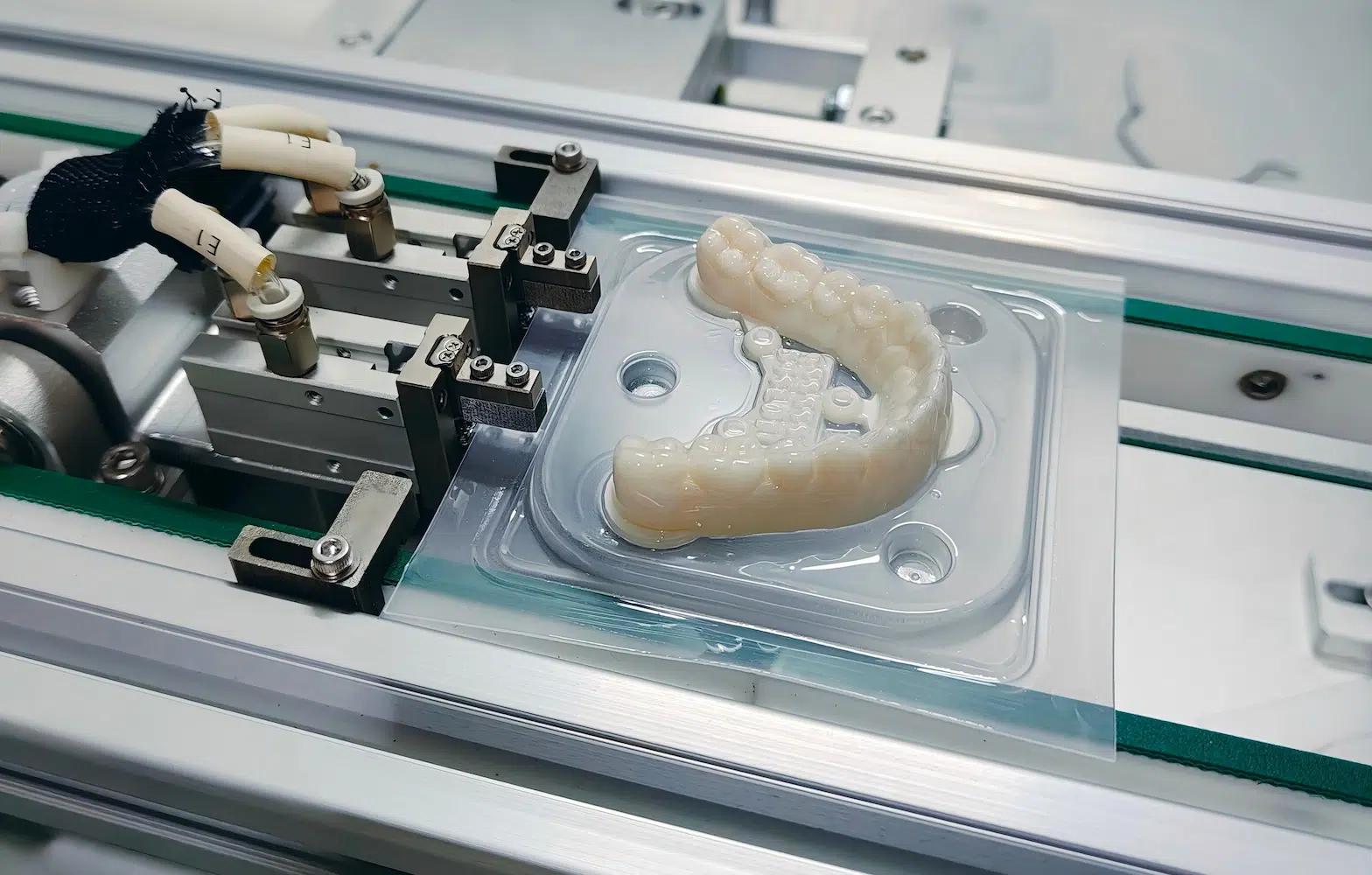

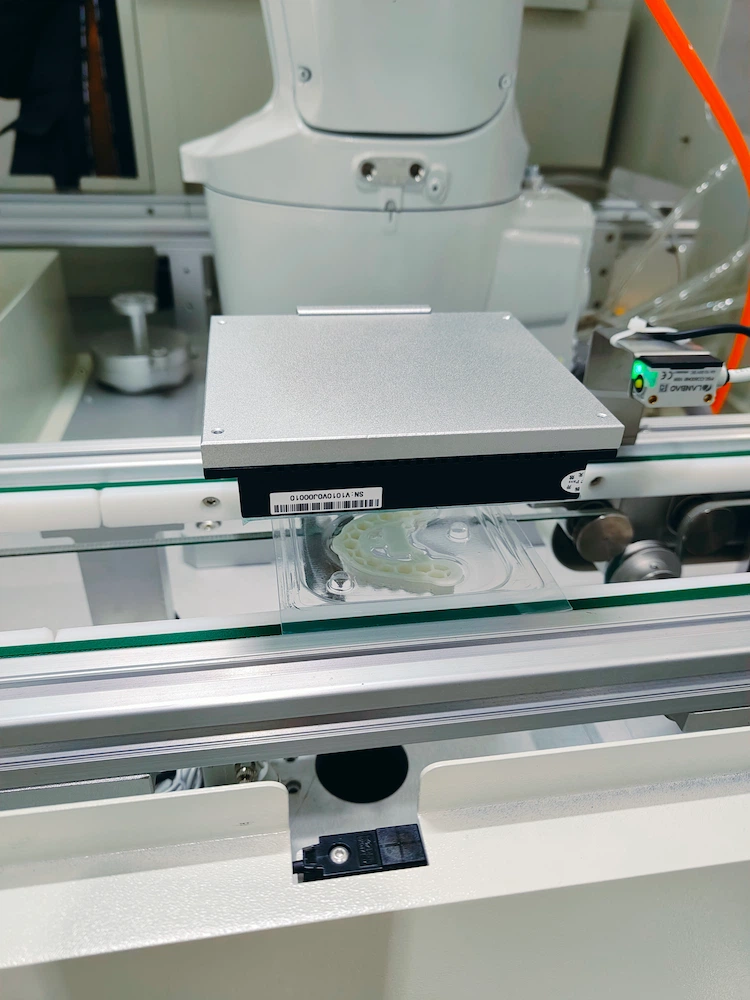

Automatic Trimming

6-Axis ABB Robot Arm Precision

Equipped with an ABB IRB1200 robot and a high-speed 40,000 rpm spindle. The system automatically generates the cutting line based on the gingival margin, ensuring smooth edges and patient comfort.

Braces All-in-One Machine

Limited space? Simplify your production line with our integrated solution. It combines Forming, Marking, and Trimming into a single unit, drastically reducing the footprint required for a dental lab.