It all starts with precise data. RayForm’s digital workflow is compatible with all major intraoral scanners (such as 3Shape, iTero, and Medit). We support direct import of STL/PLY format files, ensuring the instant transmission of patient dental data.

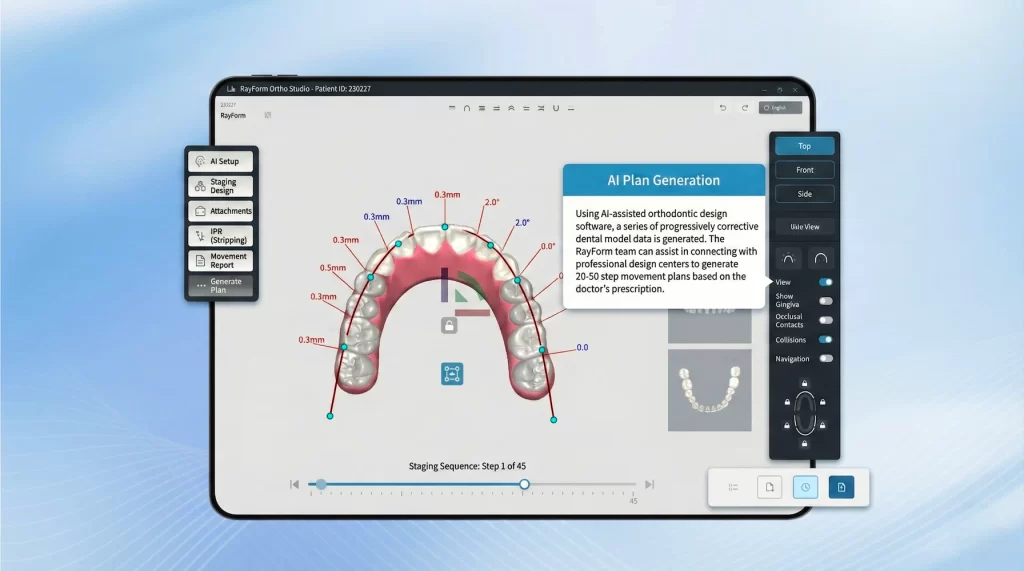

Using AI-assisted orthodontic design software, a series of progressively corrective dental model data is generated. The RayForm team can assist in connecting with professional design centers to generate 20-50 step movement plans based on the doctor’s prescription.

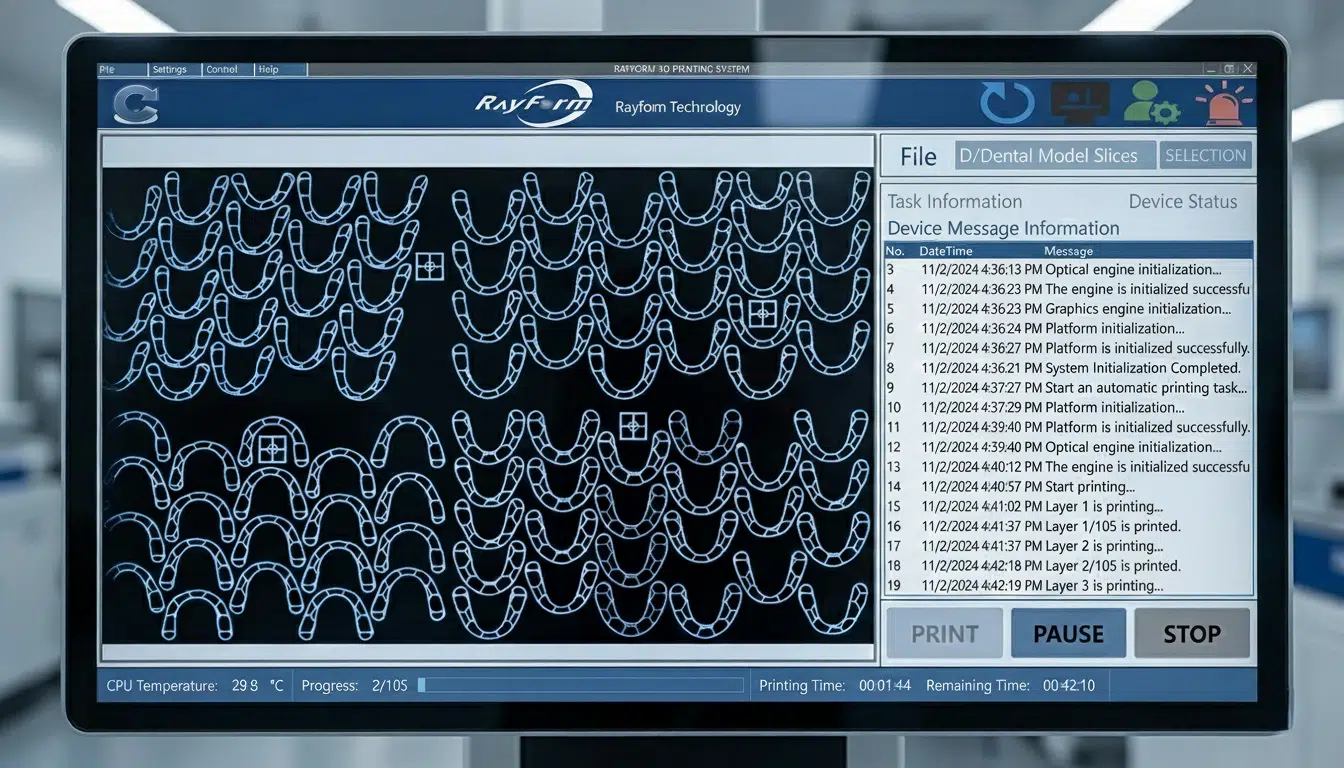

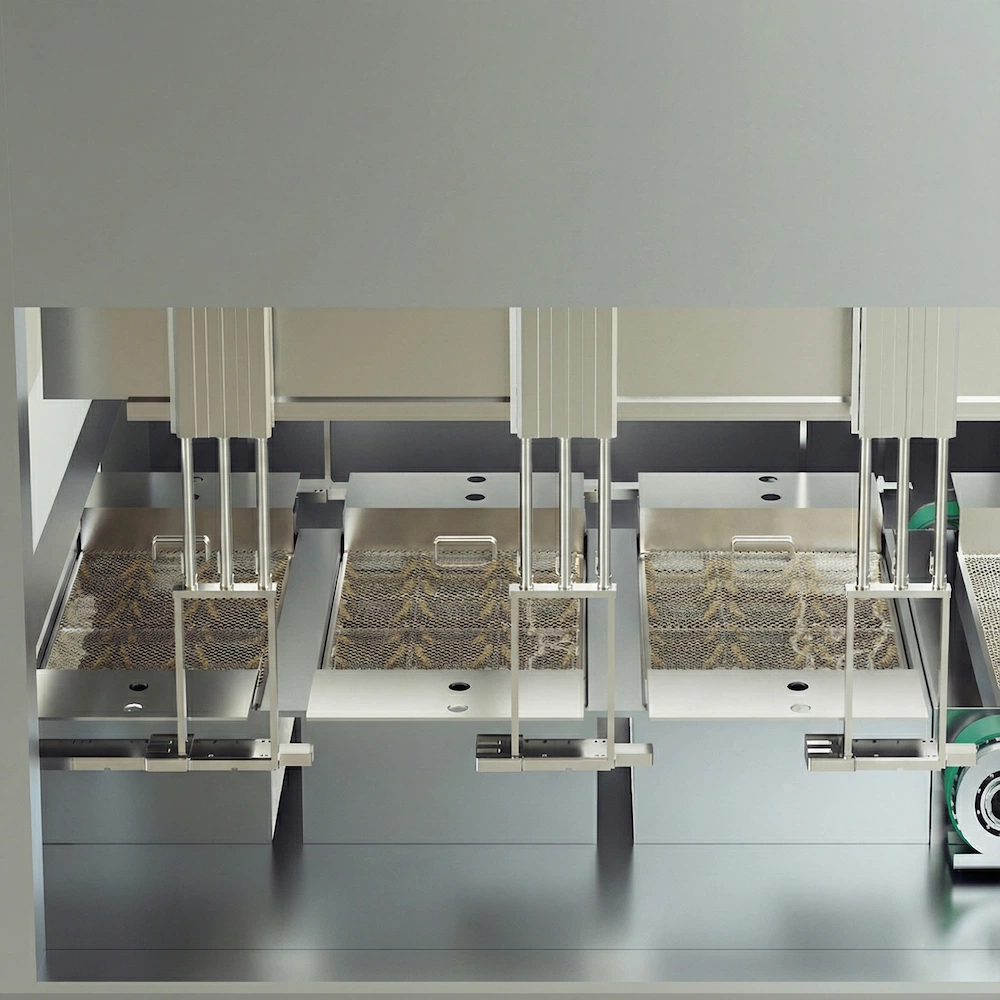

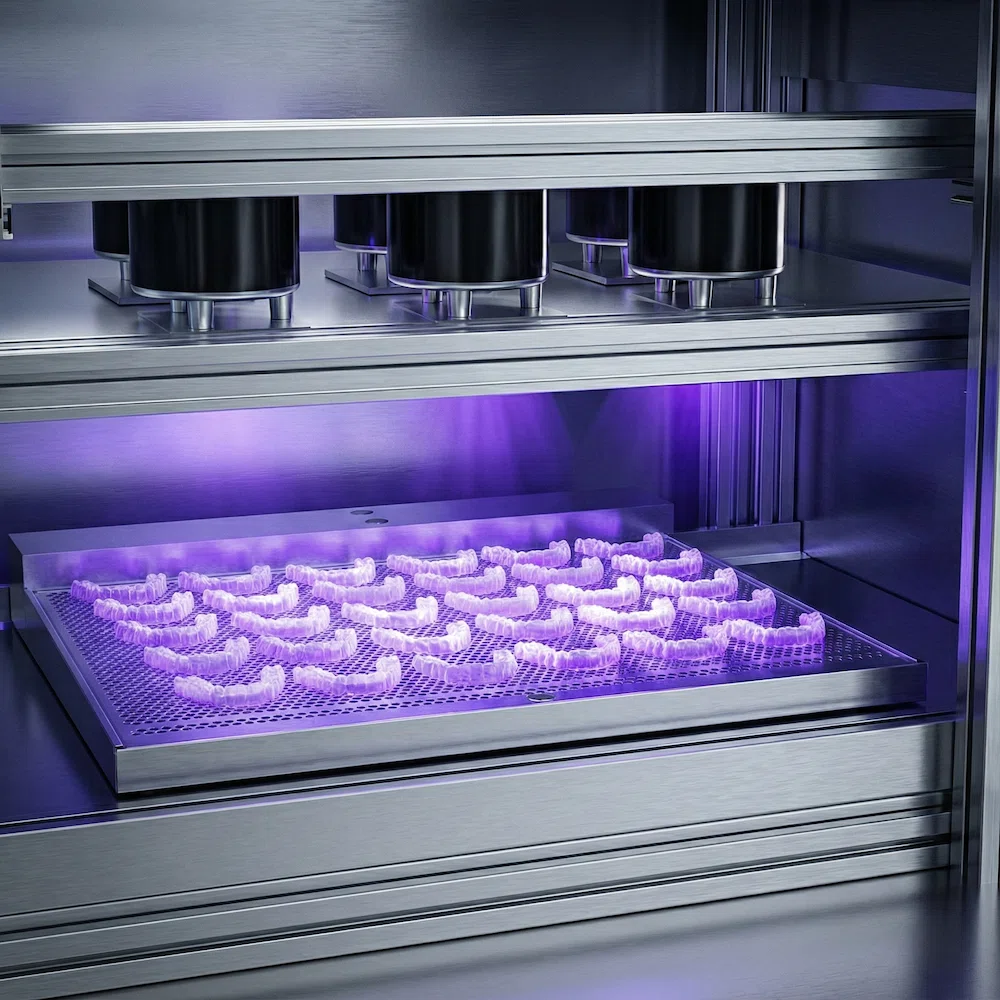

To maximize mass production efficiency, we offer intelligent nesting software. With a single click, it automatically lays out or stacks hundreds of dental model data from dozens of patients onto the printing platform and automatically adds tagging to prevent production confusion.

After printing, use isopropyl alcohol (IPA) or alcohol to remove any residual resin from the surface. RayForm provides SOP cleaning parameters and recommends a two-stage cleaning process of “coarse cleaning + fine cleaning” to ensure that the model surface is free of stickiness and to guarantee the transparency of the final dental crown.