Mass Production

DLP Solutions

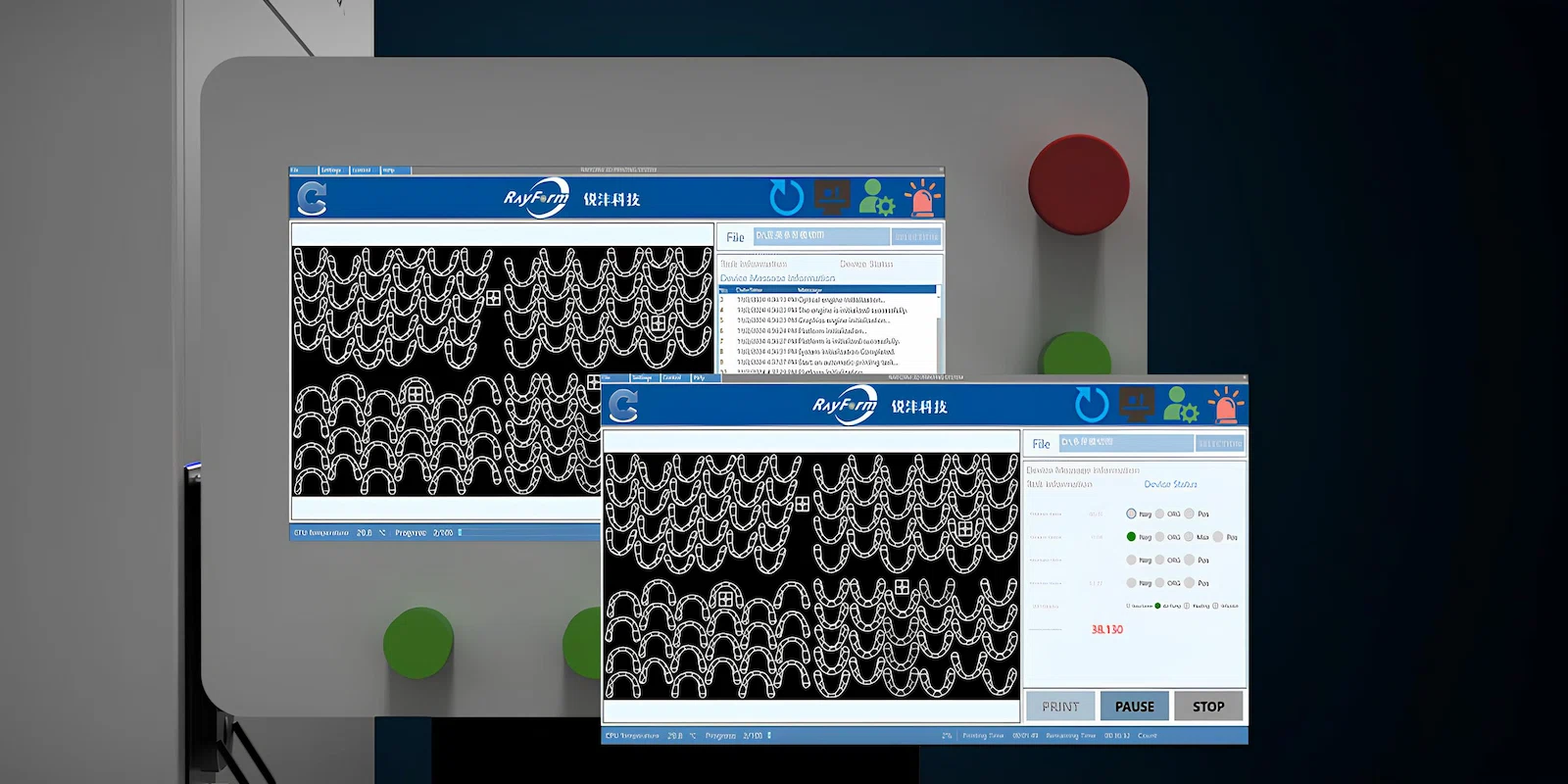

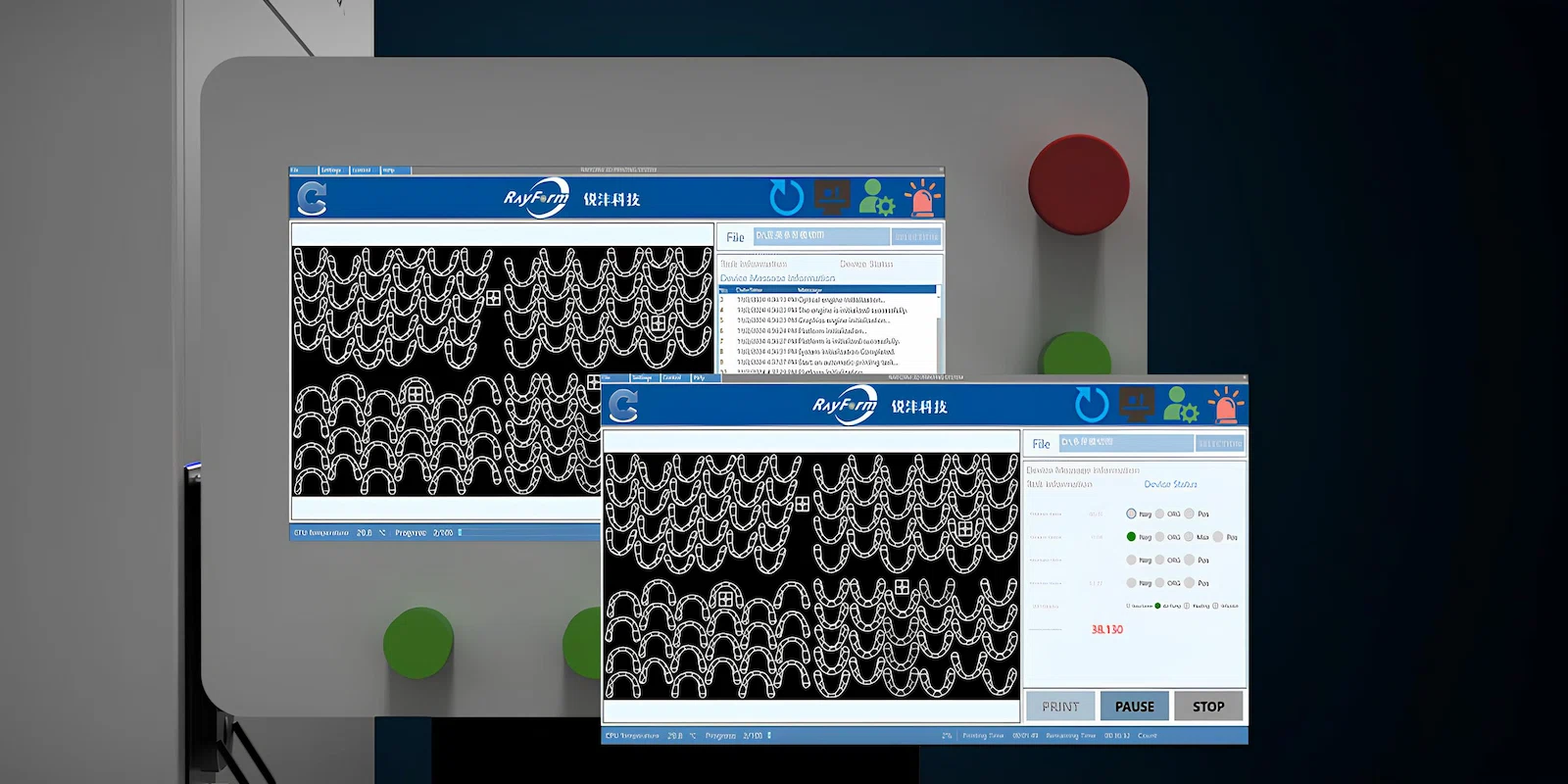

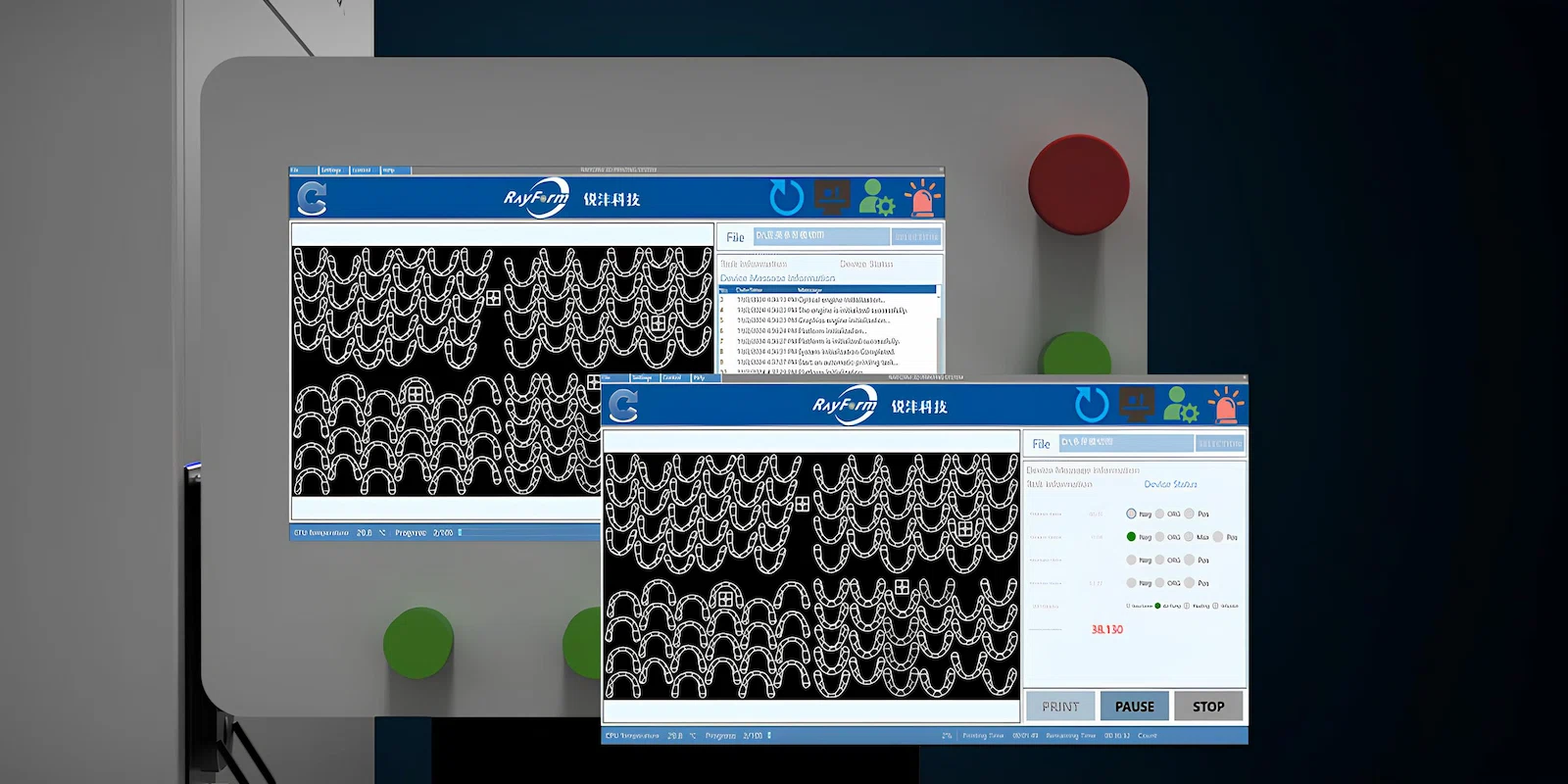

Fully automated, high-speed DLP 3D printers designed for clear aligner factories. Featuring Auto-Refilling, Auto-Removal, and Intelligent PMS Control.

Industrial DLP Series

7×24 hours unmanned automated production for dental labs.

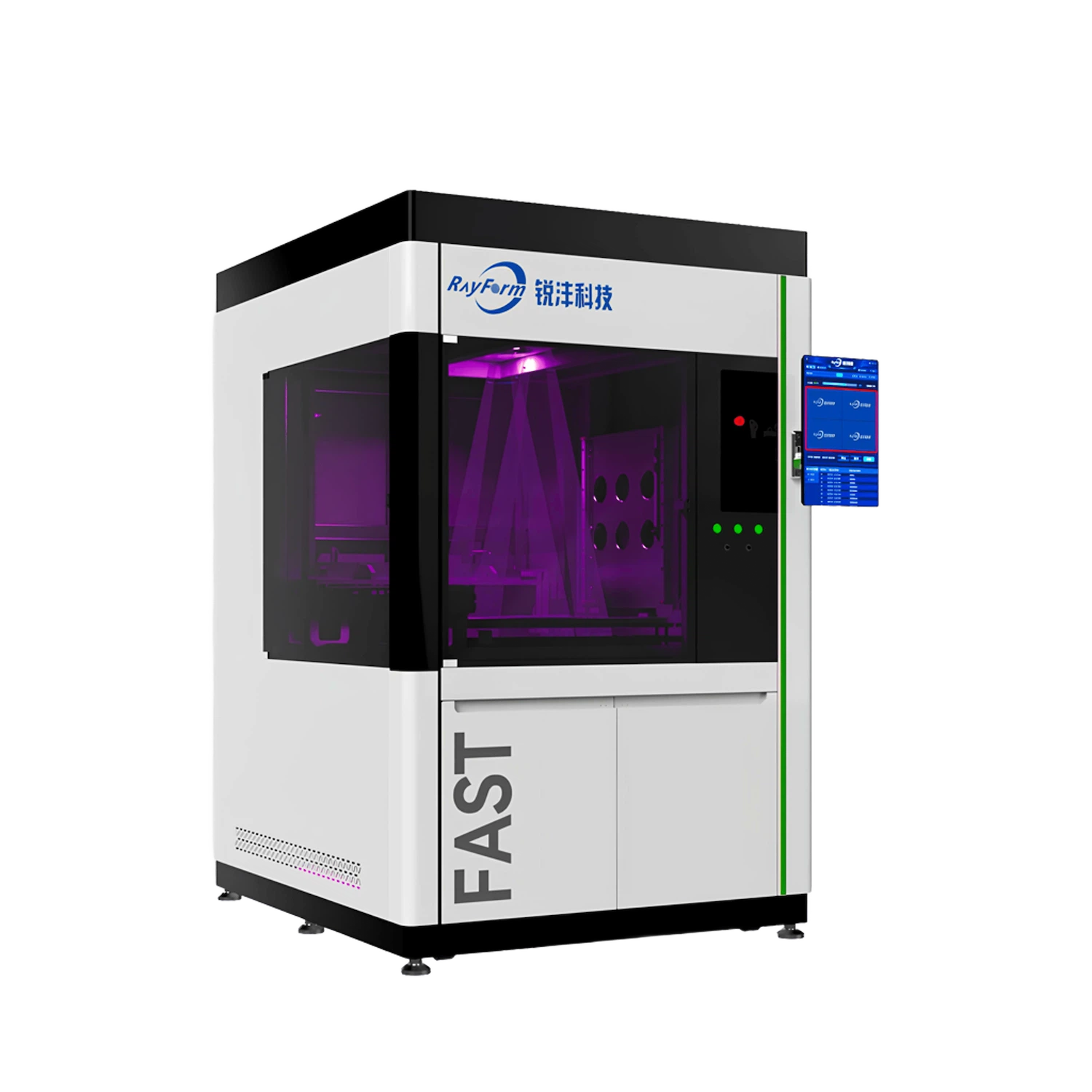

RF-8800 3D Printer

The Largest DLP Build Volume for Mass Production

Boasts a fully automated system with capabilities for automatic removal, sorting, and refilling. Adopts multi-matrix DLP technology (4x4K engines) and advanced HADP™ technology.

Key Automation Features

RF-4030 3D Printer

Flexible Solution for Dental Labs & Clinics

Uses the same advanced DLP technology as the RF8800 series but with a single 4K engine. Offers high reliability and straightforward maintenance for smaller batch needs.

Key Features

RF-4050 3D Printer

Double Engine Power for Medium-High Throughput

Equipped with 2X4K DLP optical engines for high precision and stability. Popular with dental labs and clinics requiring a balance of size and speed.

Key Features

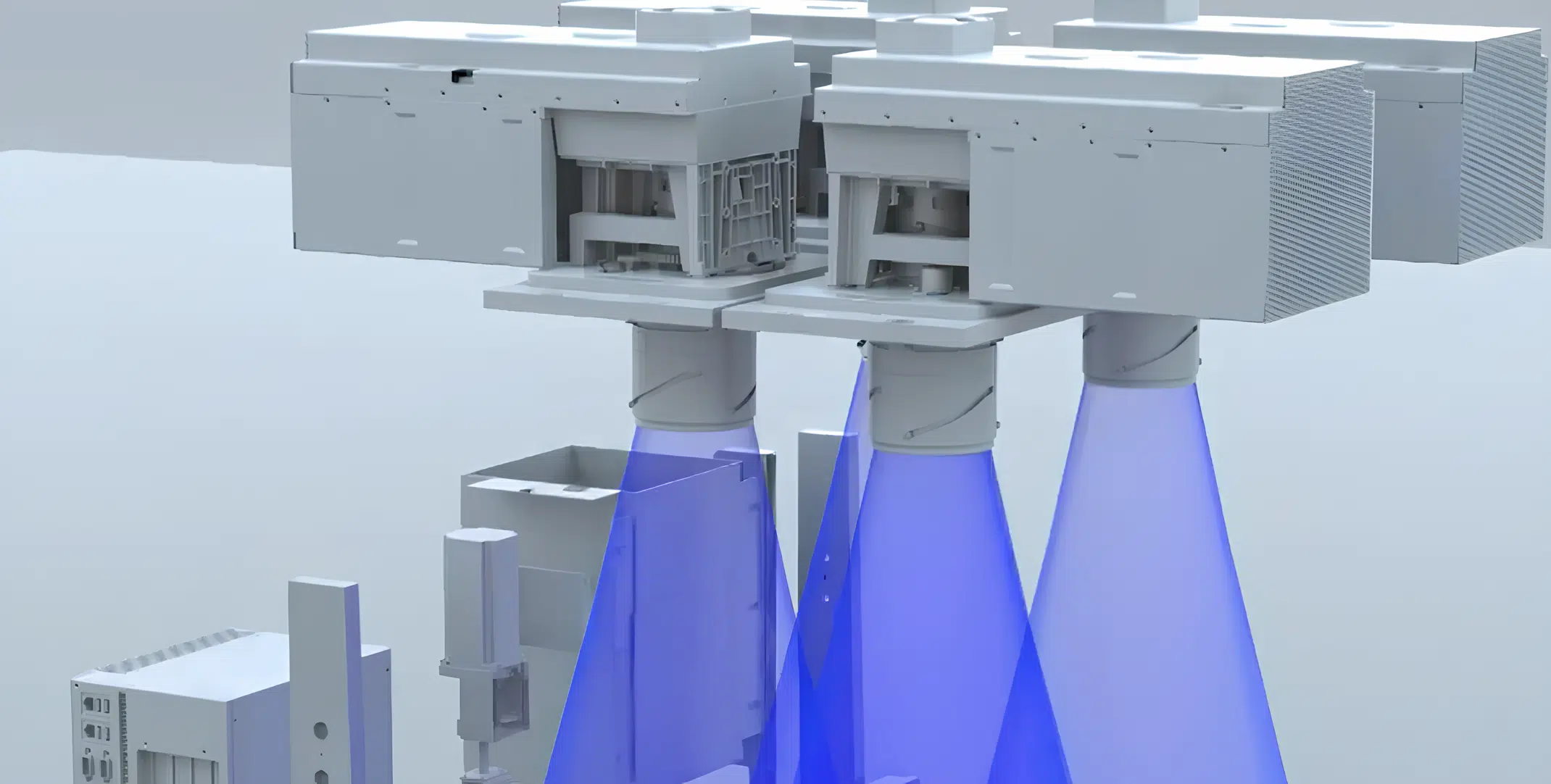

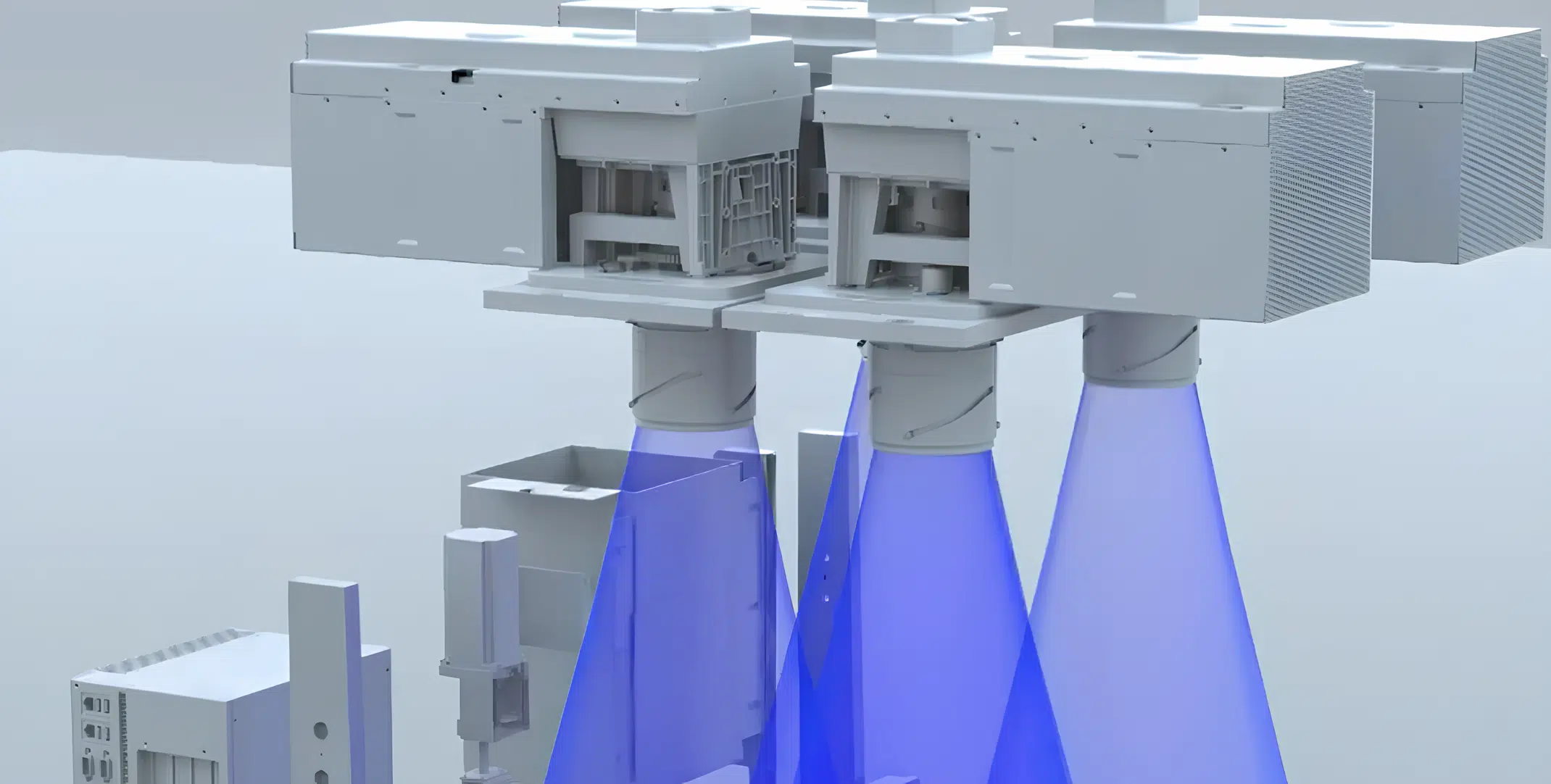

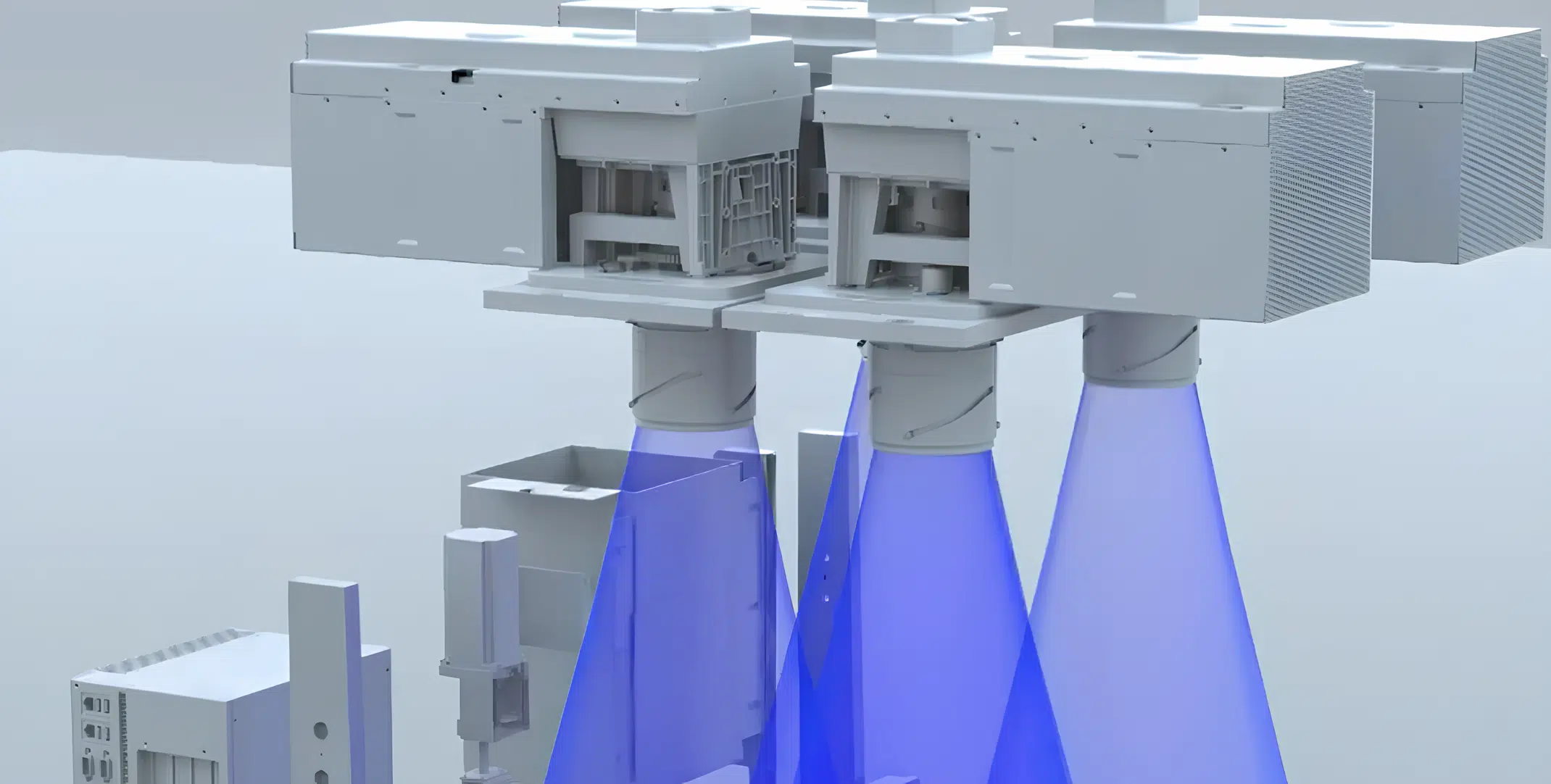

How RAYFORM 3D PRINTERS Work

By continuously scanning with light to record each layer of the pattern, the platform intelligently pushes the liquid to cover the model. This process is repeated continuously with intelligent liquid level adjustment until the procedure is completed, ensuring high speed and stability.